S-OIL to Invest $7 billion in Ulsan

“Landmark investment represents exciting new chapter in Korea’s petrochemical industry”

● S-OIL’s innovative growth from ‘oil to chemicals’

- Next-generation process facilities to produce up to 3.2 million tons of petrochemicals annually.

- Potential carbon emission reduction and improved efficiency from new technology (TC2C)

- Opportunity for improved waste heat recycling, higher energy efficiency, and fewer carbon emissions

● Aramco’s biggest ever investment into South Korea

- Aramco strongly committed to “full support” for investment-driven sustainable growth into the future

- Aramco to support world’s first commercialization of new (TC2C) technology, upgrading crude oil into petrochemical feedstock

S-OIL plans to develop a $7 billion petrochemical project in Ulsan, featuring one of the world’s largest refinery-integrated petrochemical steam crackers which will support the long term and stable delivery of building block petrochemicals to Korea and beyond.

On Nov. 17, 2022 S-OIL announced the final investment decision (FID) for the ‘Shaheen Project’ (Arabic word for Peregrine Falcon), which aims to support the energy transition in the country.

The Shaheen project is the largest ever investment made in Korea by Aramco, which holds 63.4% of the company’s shares via its subsidiary Aramco Overseas Company B.V (AOC).

The next-generation process facilities are expected to produce up to 3.2 million tons of petrochemicals annually. It follows the $4 billion phase one petrochemical expansion project completed in 2018.

The announcement coincides with a summit meeting between South Korean President Yoon Sukyeol and HRH Prince Mohammed bin Salman bin Abdulaziz Al Saud, Crown Prince and Prime Minister of the Kingdom of Saudi Arabia.

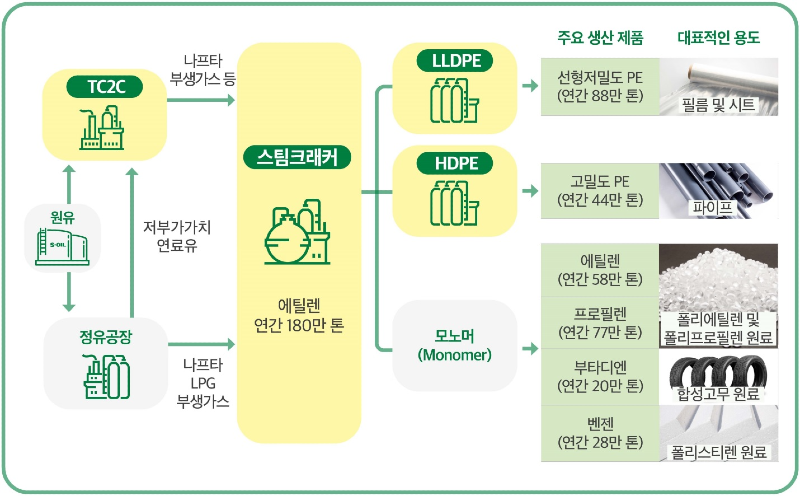

The steam cracker will deploy Aramco’s cutting edge TC2C thermal crude-to-chemicals technology, capable of producing high value petrochemicals as feedstock for plastics and other synthetic materials. The project is expected to start in 2023 with completion targeted for 2026.

S-OIL CEO Hussain Al-Qahtani said: "We have taken the first step on a great journey of development. With the full support of the governments of our two countries, our successful track record in delivering major projects and the outstanding professionalism of our team, we are confident that Shaheen will not only diversify our portfolio towards chemicals but also deliver industry-leading energy efficiency.”

Shaheen will mobilize as many as 17,000 workers per day during construction and generate over KRW 3 trillion in value to the Ulsan local construction industry.

The project will also support the stable supply of petrochemical feedstock to South Korea.

The steam cracker will treat by-products from crude processing including naphtha, off-gas and other feedstocks to produce ethylene, propylene, butadiene and benzene, among other basic chemicals. The plant will also produce polyethylene used as feedstock for making plastics and other synthetic materials.

The TC2C process utilizes low value heavy oil which is processed in the existing refinery into steam cracker feedstock. This is the first time Aramco’s TC2C technology has been commercialized, with the hope of giving the new project a competitive edge when compared to older generation crackers.

Shaheen will also support S-OIL's ambition to operate more efficiently by recovering and recycling waste heat from the steam cracker and improved overall energy efficiency.

Upon project completion, S-OIL's chemical yield based on volume will more than double from the current level (12%) to 25%.

In relation to this, S-OIL held EPC contract awarding ceremony with Hyundai Engineering & Construction, Hyundai Engineering and Lotte Engineering & Construction held at Korea Chamber of Commerce and Industries on Nov. 17th bringing the Project EPC to full track.